The Challenge

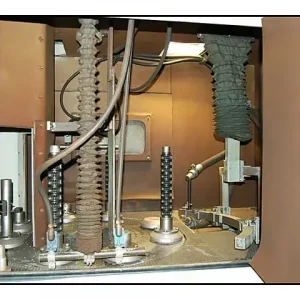

Manufacturers in Nagpur demand superior finishes, precise deburring, and effective surface preparation across a range of components. While traditional dry blasting can be effective, it often generates excessive dust and can be too aggressive for delicate parts or intricate features.

The AeroWheel Surface Finishing Solution

AeroWheel Surface Finishing redefines surface preparation with our advanced Wet Blast Cabinets. Discover the advantages for Nagpur manufacturers:

- Superior Finishes: Achieve smooth, uniform, and aesthetically pleasing surfaces on various materials.

- Gentle and Precise Deburring: Effectively remove burrs without damaging delicate parts or features.

- Enhanced Surface Preparation: Create ideal surfaces for painting, coating, or bonding processes.

- Cleaner and Safer Operation: Wet blasting minimizes dust creation for a healthier and cleaner work environment.

Features and Customization

AeroWheel Surface Finishing’s Wet Blast Cabinets are designed for flexibility and adaptability in Nagpur’s diverse industries:

- Diverse Media Options: Utilize various slurry types and abrasive media to match your specific applications.

- Precision Control: Adjustable pressure, slurry flow, and blast duration for optimal results on varying parts.

- Range of Sizes: Select the perfect cabinet size to accommodate your production volume and workpiece dimensions.

- Optional Automation: Integrate automation features to streamline workflows and improve throughput.

Results and Support

Choose AeroWheel Surface Finishing as your Wet Blast Cabinet manufacturer in Nagpur and experience:

- Improved Product Quality: Deliver components with consistently flawless surface finishes that exceed expectations.

- Increased Productivity: Streamline your workflows, reduce rework, and minimize cleaning time.

- Cost Savings: Reduce abrasive media consumption and post-blasting cleanup efforts.

- Dedicated Support: Rely on our expert team for installation, guidance, training, and ongoing maintenance.

Wet blast cabinets are essential for various industries, including automotive, aerospace, electronics, and metal fabrication, where precise surface finishing is critical for product aesthetics and functionality. These cabinets utilize a slurry mixture of water, abrasive media, and additives to achieve controlled surface treatments, offering benefits such as reduced dust, improved visibility, and enhanced surface cleanliness. Therefore, selecting the right manufacturer of wet blast cabinets in Nagpur is crucial for achieving superior surface finishing outcomes.

Trusted manufacturers of wet blast cabinets in Nagpur offer a diverse range of equipment tailored to different production requirements and material specifications. From compact, benchtop models suitable for small-scale operations to large, automated cabinets for high-volume production, these manufacturers provide solutions suited to the specific needs of each industry sector. With precision engineering and innovative technologies, their wet blast cabinets ensure efficient surface finishing processes while minimizing material waste and maximizing productivity.

Moreover, renowned manufacturers prioritize quality assurance throughout the manufacturing process, utilizing high-grade materials and adhering to stringent industry standards. By investing in premium-quality equipment, businesses in Nagpur can enhance surface finishing precision, reduce rework, and improve product quality.

In addition to offering cutting-edge equipment, top wet blast cabinet manufacturers in Nagpur provide comprehensive support services, including installation, training, maintenance, and technical assistance. Their experienced teams collaborate closely with clients to understand their specific requirements and operational challenges, offering tailored solutions and ongoing support to optimize equipment performance and productivity.

Call to Action

Elevate your surface finishing capabilities in Nagpur. Contact AeroWheel Surface Finishing to explore our Wet Blast Cabinet solutions and request a personalized consultation.

Reviews

There are no reviews yet.