The Challenge

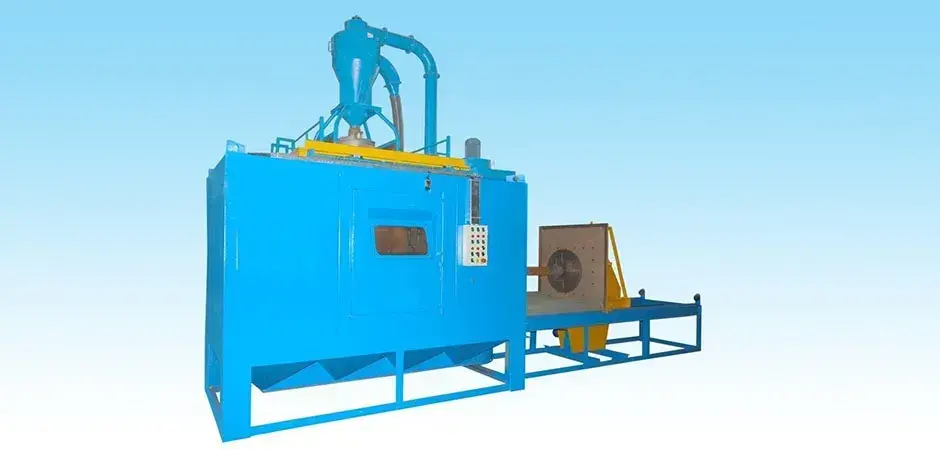

Nagpur manufacturers across industries like textiles, paper, plastics, and metals rely on rolls with specific surface textures or patterns for optimal product quality. Traditional roll finishing methods may lack precision, consistency, or versatility, hindering efficiency and potentially impacting final product performance.

The AeroWheel Surface Finishing Advantage

AeroWheel Surface Finishing empowers Nagpur industries with cutting-edge Roll Etching Machines. Experience the advantages:

- Precise Etching and Texturing: Achieve the exact surface profiles or designs necessary for your application.

- Versatile Applications: Etch a wide range of roll materials and compositions for various industries.

- Repeatability and Consistency: Ensure uniform etching results across your rolls for reliable product outcomes.

- Customization for Your Needs: Machines tailored to your roll sizes, etching requirements, and production volume.

- Enhanced Roll Functionality: Improve grip, traction, release properties, or aesthetic qualities.

Features and Customization

AeroWheel Surface Finishing understands the diverse needs of Nagpur manufacturers. Our Roll Etching Machines offer:

- Diverse Etching Techniques: Choose from chemical, laser, or electrochemical etching based on your requirements.

- Adjustable Parameters: Control etching depth, pattern density, and other parameters for precision results.

- Roll Capacity Options: Accommodate various roll diameters and lengths for diverse production needs.

- Automation Integration: Streamline your workflow with automation options for roll loading and unloading.

Proven Results and Customer Commitment

AeroWheel Surface Finishing is the top choice for Roll Etching Machine manufacturers in Nagpur. Our clients benefit from:

- Improved Product Quality: Deliver consistently flawless products thanks to optimized roll performance.

- Increased Production Efficiency: Reduce downtime and enhance throughput with reliable roll etching processes.

- Competitive Advantage: Create unique roll textures or designs that differentiate your products.

- Expert Support: Rely on our team for installation, training, maintenance, and ongoing application support.

Roll etching machines are essential for various industries, including metal fabrication, printing, and electronics, where precise surface treatment is critical for product functionality and aesthetics. These machines utilize chemical or mechanical processes to remove material from the surface of rolls, achieving the desired texture, pattern, or roughness. Therefore, selecting the right manufacturer of roll etching machines in Nagpur is crucial for achieving superior surface treatment outcomes.

Trusted manufacturers of roll etching machines in Nagpur offer a diverse range of equipment tailored to different roll sizes, material compositions, and surface treatment requirements. From manual, benchtop machines suitable for small-scale operations to fully automated systems for high-volume production, these manufacturers provide solutions suited to the specific needs of each industry sector. With precision engineering and innovative technologies, their roll etching machines ensure efficient surface treatment processes while minimizing material waste and maximizing productivity.

Moreover, renowned manufacturers prioritize quality assurance throughout the manufacturing process, utilizing high-grade materials and adhering to stringent industry standards. By investing in premium-quality equipment, businesses in Nagpur can enhance surface treatment efficiency, reduce rework, and improve overall product quality.

In addition to offering cutting-edge equipment, top roll etching machine manufacturers in Nagpur provide comprehensive support services, including installation, training, maintenance, and technical assistance. Their experienced teams collaborate closely with clients to understand their specific requirements and operational challenges, offering tailored solutions and ongoing support to optimize equipment performance and productivity.

Call to Action

Transform your roll finishing capabilities in Nagpur. Contact AeroWheel Surface Finishing today to learn more about our Roll Etching Machines and explore solutions tailored to your needs.

Reviews

There are no reviews yet.