The Challenge

Manufacturers in Nagpur require versatile blasting solutions that deliver effective cleaning and surface preparation while controlling dust and minimizing abrasive consumption. Traditional blast cabinets can lead to dust-filled workspaces, abrasive waste, and potential inefficiencies.

The AeroWheel Surface Finishing Advantage

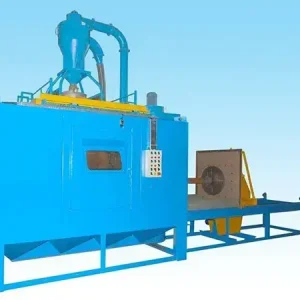

AeroWheel Surface Finishing introduces Suction/Vacuum Blast Cabinets, the ideal solution for various Nagpur industries. Experience these advantages:

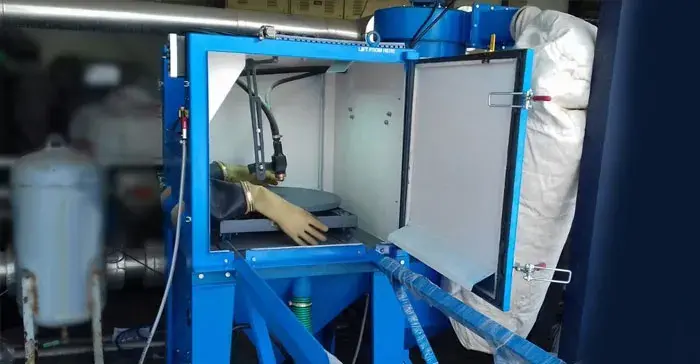

- Contained Cleaning: The cabinet design prevents abrasive and dust from escaping, creating a cleaner workspace.

- Efficient Abrasive Usage: The integrated abrasive recovery and recycling system minimizes waste.

- Versatile Applications: Suitable for cleaning, deburring, etching, and preparing various components and materials.

- Compact Footprint: Perfect for facilities with limited floor space looking to optimize their workflow.

Features and Customization

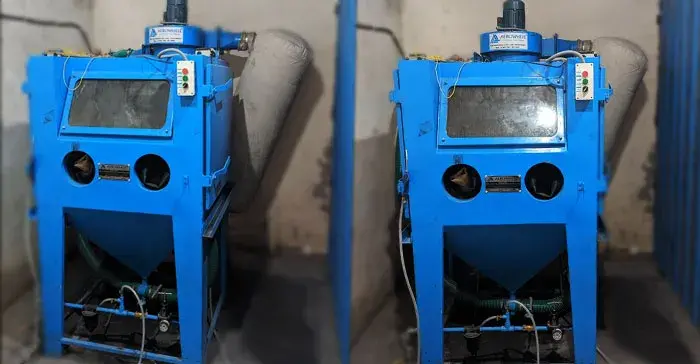

AeroWheel Surface Finishing’s Suction/Vacuum Blast Cabinets are designed for adaptability and performance:

- Adjustable Blast Pressure: Customize cleaning intensity for delicate or robust parts and various applications.

- Diverse Abrasive Options: Select the ideal abrasive media to match your specific surface finishing requirements.

- Ergonomic Design: Easy-access doors and optimal visibility for efficient and user-friendly operation.

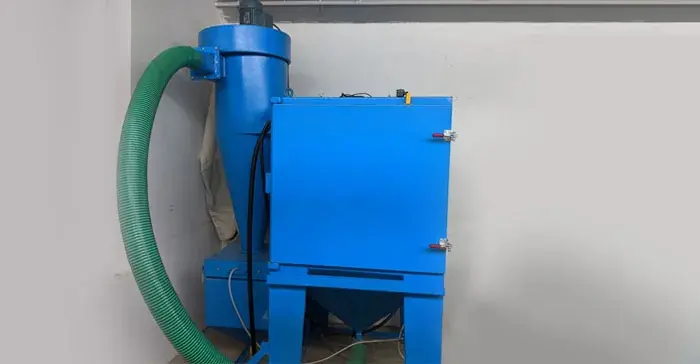

- Dust Collection Integration: Seamlessly connects to dust collectors for maintaining a clean environment.

Why Choose AeroWheel Surface Finishing

For the highest quality Suction/Vacuum Blast Cabinets in Nagpur, manufacturers trust AeroWheel because:

- Expertise in Surface Finishing: We understand the cleaning and preparation challenges facing your industry.

- Focus on Efficiency: Our cabinets are designed to reduce abrasive waste and optimize your blasting processes.

- Custom-Engineered Solutions: We tailor cabinets to your specific needs and production workflow.

- End-to-End Support: Benefit from installation, commissioning, training, and ongoing maintenance services.

Suction/vacuum blast cabinets are essential for various industries, including automotive, aerospace, metal fabrication, and electronics, where thorough surface preparation is critical for product quality and performance. These cabinets utilize a combination of abrasive media and suction/vacuum technology to remove contaminants and coatings from surfaces efficiently. Therefore, selecting the right manufacturer of suction/vacuum blast cabinets in Nagpur is crucial for achieving superior surface preparation outcomes.

Trusted manufacturers of suction/vacuum blast cabinets in Nagpur offer a diverse range of equipment tailored to different production requirements and material specifications. From compact, benchtop models suitable for small-scale operations to large, automated cabinets for high-volume production, these manufacturers provide solutions suited to the specific needs of each industry sector. With precision engineering and innovative technologies, their suction/vacuum blast cabinets ensure efficient surface preparation processes while minimizing material waste and maximizing productivity.

Moreover, renowned manufacturers prioritize quality assurance throughout the manufacturing process, utilizing high-grade materials and adhering to stringent industry standards. By investing in premium-quality equipment, businesses in Nagpur can enhance surface preparation efficiency, reduce rework, and improve product quality.

In addition to offering cutting-edge equipment, top suction/vacuum blast cabinet manufacturers in Nagpur provide comprehensive support services, including installation, training, maintenance, and technical assistance. Their experienced teams collaborate closely with clients to understand their specific requirements and operational challenges, offering tailored solutions and ongoing support to optimize equipment performance and productivity.

Call to Action

Elevate your contained blasting operations in Nagpur. Contact AeroWheel Surface Finishing to explore our Suction/Vacuum Blast Cabinet solutions and receive a personalized quote.

Reviews

There are no reviews yet.