The Challenge

Manufacturers in Nagpur handling batch cleaning and surface finishing of castings and forgings face bottlenecks and inefficiencies. Relying on manual blasting methods leads to inconsistent results, time-consuming production cycles, and potential labor shortages.

The AeroWheel Surface Finishing Advantage

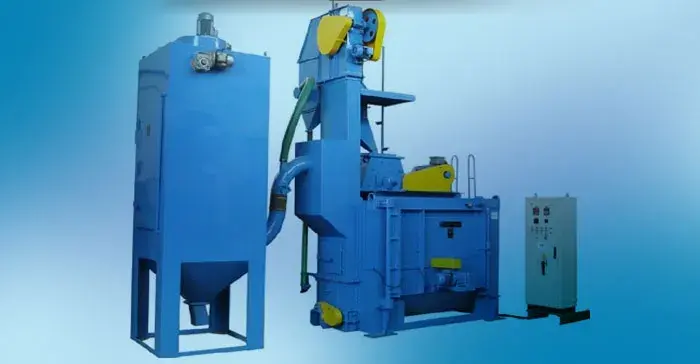

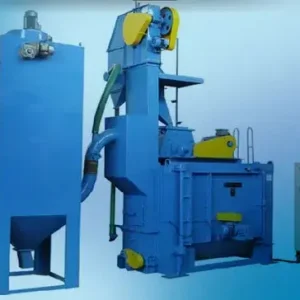

AeroWheel Surface Finishing transforms your batch processing capabilities with our state-of-the-art Airless Swing Table Shot Blasting Machines. Experience these key benefits:

- High-Speed Cleaning: Powerful blast wheels propel abrasive at high velocity for rapid batch processing.

- Uniform and Quality Finishes: Ensure consistent surface preparation quality across various components.

- Reduced Labor and Downtime: Automated loading and unloading optimizes your workforce and minimizes downtime.

- Eco-conscious Blasting: Airless technology eliminates compressed air consumption and lowers operational costs.

Features and Applications

AeroWheel Surface Finishing’s Airless Swing Table Shot Blasting Machines are designed for versatility and flexibility in Nagpur’s manufacturing sectors:

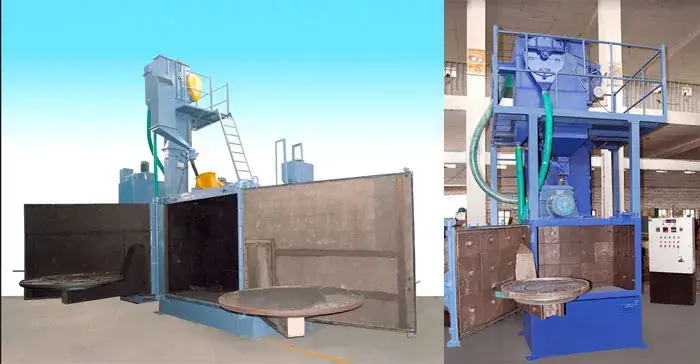

- Single or Double Table Configuration: Choose layouts to match your specific production volume needs.

- Adjustable Blast Cycles: Customize blasting time based on part types and required surface finish.

- Ideal Applications: Perfect for de-sanding castings, de-scaling forgings, removing surface contaminants, and preparing surfaces for further processing.

Customer Success and Commitment

AeroWheel Surface Finishing is the leading Airless Swing Table Shot Blasting Machine manufacturer in Nagpur. Our clients benefit from:

- Increased Throughput: Dramatically boost production volume for your batch operations.

- Improved Consistency: Achieve uniform quality across various batches, enhancing product reliability.

- Optimized Production Costs: Reduce labor costs, lower abrasive consumption, and minimize downtime.

- Expert Support: Rely on our experienced team for installation, training, and ongoing maintenance support.

Airless swing table shot blasting machines are essential for various industries, including automotive, aerospace, foundries, and metal fabrication, where thorough surface treatment is critical for product quality and performance.

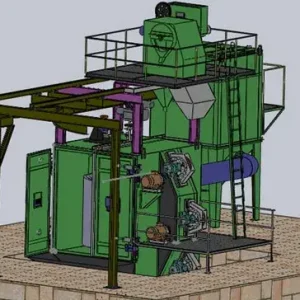

These machines facilitate efficient surface treatment by propelling abrasive media at high velocity onto workpieces mounted on a rotating table, ensuring uniform coverage and consistent results. Therefore, selecting the right manufacturer of airless swing table shot blasting machines in Nagpur is crucial for achieving superior surface treatment outcomes.

Trusted manufacturers of airless swing table shot blasting machines in Nagpur offer a diverse range of equipment tailored to different production requirements and material specifications.

From compact, manual machines suitable for small-scale operations to fully automated systems for high-volume production, these manufacturers provide solutions suited to the specific needs of each industry sector. With precision engineering and innovative technologies, their airless swing table shot blasting machines ensure efficient surface treatment processes while optimizing energy consumption and minimizing waste.

Moreover, renowned manufacturers prioritize quality assurance throughout the manufacturing process, utilizing high-grade materials and adhering to stringent industry standards. By investing in premium-quality equipment, businesses in Nagpur can enhance surface treatment efficiency, reduce rework, and improve product quality.

In addition to offering cutting-edge equipment, top airless swing table shot blasting machine manufacturers in Nagpur provide comprehensive support services, including installation, training, maintenance, and technical assistance. Their experienced teams collaborate closely with clients to understand their specific requirements and operational challenges, offering tailored solutions and ongoing support to optimize equipment performance and productivity.

Call to Action

Transform your batch processing capabilities in Nagpur. Contact AeroWheel Surface Finishing to discuss your specific requirements for Airless Swing Table Shot Blasting Machines and explore our solutions.

Virkam –

Greetings artisans! I’m thrilled to share my experience with the Airless Swing Table Shot Blasting Machine, a true gem in surface preparation. Sourced from a top-notch manufacturer in India, this machine has become the heartbeat of my Jodhpur workshop.

Straight to the point – the manufacturer’s expertise shines through. Built to tackle the intricacies of Jodhpur’s industrial needs, this machine is a testament to quality craftsmanship. The durability and precision it brings are a perfect match for our city’s demanding projects.

The airless swing table feature is a game-changer. It offers unparalleled versatility, allowing me to easily position and treat various components. Whether it’s intricate metalwork or large surfaces, the swing table design handles it effortlessly, maximizing efficiency and minimizing downtime.

Living in Jodhpur, dust and debris are constant companions. However, this machine’s integrated dust collector ensures a clean workspace, promoting safety and maintaining a healthier environment for all craftsmen involved. It’s a small yet crucial detail that sets it apart.

The efficiency of the airless shot blasting mechanism is truly commendable. Quick, precise, and with adjustable settings, it adapts seamlessly to the unique requirements of each project. This not only saves time but also optimizes abrasive usage, making it a cost-effective choice for long-term projects.

In a nutshell, the Airless Swing Table Shot Blasting Machine from an esteemed Indian manufacturer has elevated the standards in my Jodhpur workshop. If you’re in the market for precision, versatility, and durability, this machine is a must-have. Here’s to effortless surface preparation and flawless finishes – cheers, fellow craftsmen!